LISSMAC SBM-M S2: Dry, Deburr Top & Bottom in a Single Pass

conventional grinders, LISSMAC systems win over customers with more efficient processing times

and labor savings of up to 60%.

Consistent edges on both outside and inside contours.

Deburring of various materials such as stainless steel, mild steel & vinyl covered stainless steel.

Deburr sheets covered in protective film without damaging the film.

Dry processing system, no water, no rust.

Different grain of the sand paper available (24 – 120 grain).

No damage to the parent metal - tolerance remains intact.

Easy operation due to the central control panel.

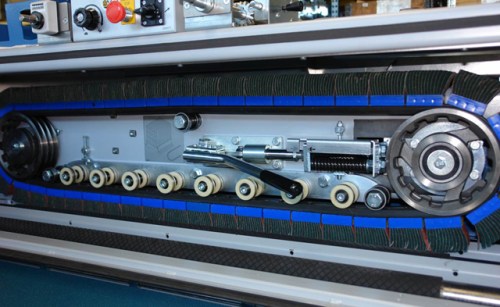

Hydraulic belt tension – fast tool change.

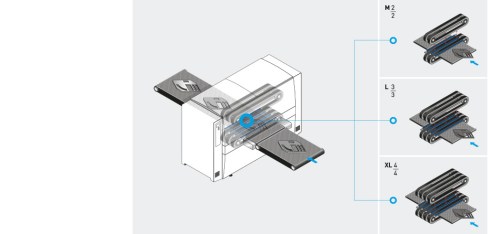

Lissmac SBM-S2 Both sides - One Work Step

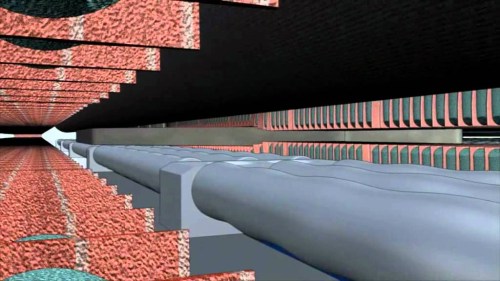

The LISSMAC innovation – In the dry processing method, the highly efficient double-sided processing of all punched and cut contours (outside and inside contours) parts in only one pass.

Double-sided synchronous processing offers highest productivity for LISSMAC customers.

The processing principle of LISSMAC systems guarantees across the entire working with optimal tool utilization because the processing of the workpiece is always crossways to the feed direction.

Features

Deburring and edge rounding of sheet metal up to 2 inch sheet thickness

Two models available, in 40 inch & 60 inch widths

Highest quality in edge rounding while deburring internal and external contours

No damage to the parent metal – tolerances remain intact

Deburr parts covered in protective film without damaging the film

Dry machining - dust extraction available as an option

Infinitely variable feed speed

Easy handling and maintenance

Hydraulic belt tension – fast tool change

Upper and lower units separated electrically adjustable and can be switched off

Simplified operation via a central controller

Tool wear indicator

Compact, modular design with low space requirements