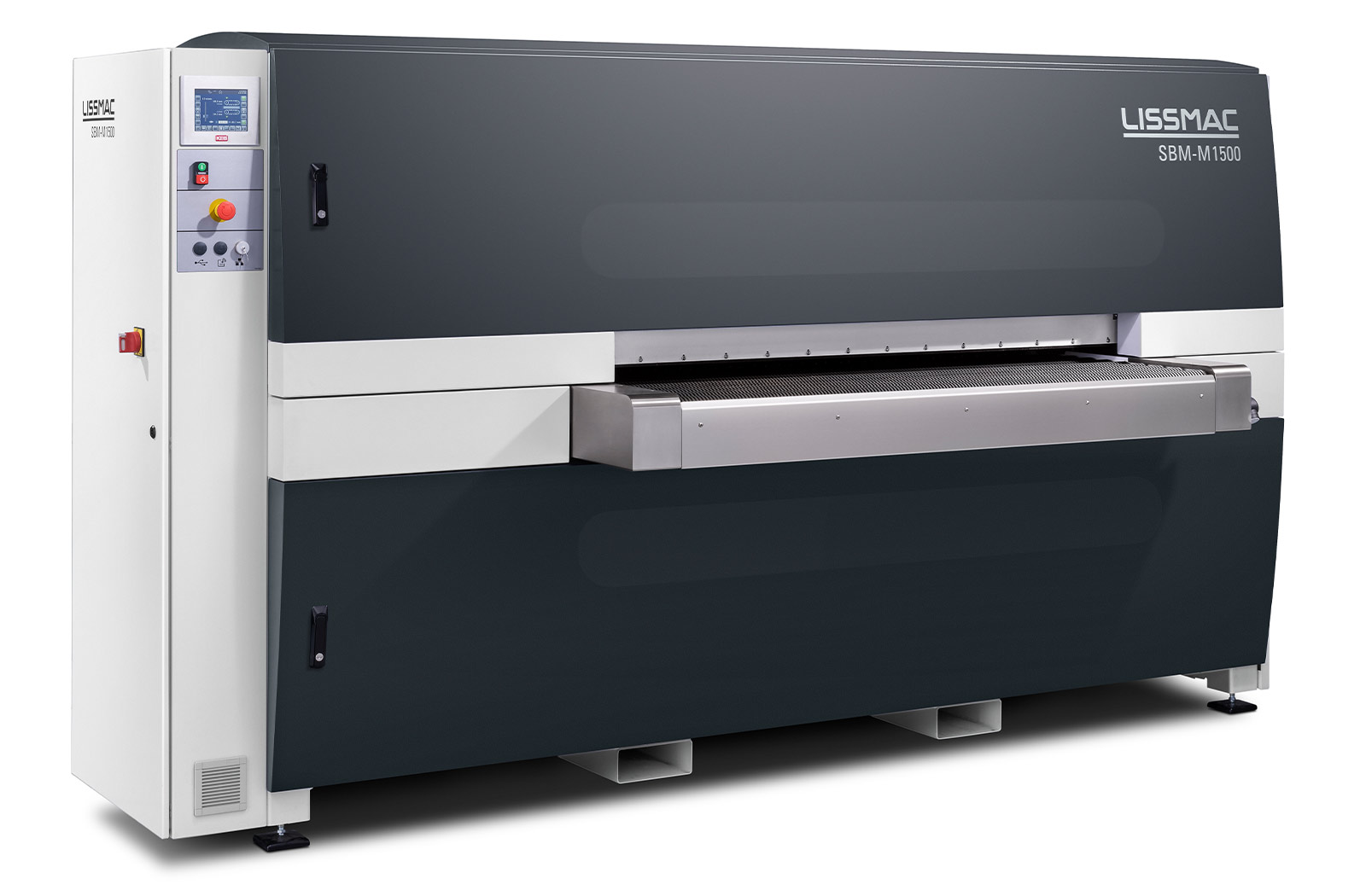

LISSMAC SBM-M D2: Dry Slag Removal Top & Bottom in a Single Pass

The SBM-M D2 grinding and deburring machine was developed for the mechanical removal of slag on both sides of thick sheet metal parts. It is ideal for machining plasma and flame-cut parts after oxy-fuel and plasma cutting. The mechanical chipping off of the slag with the slag hammer saves costly machining operations. The SBM-M D2 works on both sides when deburring sheet metal or when removing slag, saving the time an effort of turning over heavy components. The LISSMAC machine concept guarantees optimal ergonomics and makes work easier thanks to its machine processes. The deburring machines can be linked with other LISSMAC machines.

Description

LISSMAC SBM-M D2

The SBM-M D2 grinding and deburring machine was developed for the mechanical removal of slag on both sides of thick sheet metal parts. It is ideal for machining plasma and flame-cut parts after oxy-fuel and plasma cutting. The LISSMAC SBM-M D2 mechanically chips off of the slag with the slag pins saving costly secondary operations. The SBM-M D2 works on both sides when deburring sheet metal or when removing slag, saving the time an effort of turning over heavy components. The LISSMAC machine concept guarantees optimal ergonomics and makes work easier thanks to its unique process. The SBM0M D2 can be linked with other LISSMAC machines.

youtube_url

https://www.youtube.com/watch?v=70RR6w64Zug

Youtube URL address

https://www.youtube.com/watch?v=HZs1acsUaak

Youtube URL address