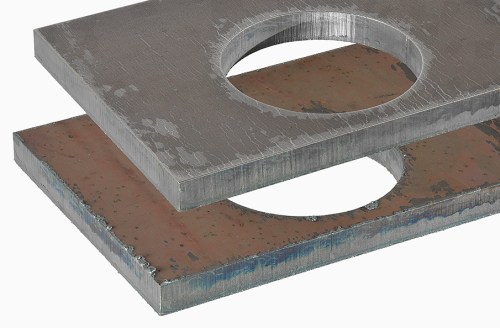

LISSMAC SBML G1S2: Dry, Deburr, Edge Round, Top & Bottom in a Single Pass

Both Sides - One Work Step

The LISSMAC innovation – In the dry processing method, the highly efficient double-sided processing of all punched and cut contours (outside and inside contours) parts in only one pass.

Features

Deburring and edge rounding of parts up to 2 inch material thickness

Available in two working widths; 39.5 inch & 59 inch

Removal of spots and dross on the sheet metal surface

Processing both sides of the parts simultaneously eliminates the need of turning larger parts and processing them for a second time

Consistent edges on all outside and inside contours

Dry operation – no hazardous grinding residues or complex drying systems

Easy operation and maintenance

Modular design, compact and sturdy construction

Each tool unit can be operated and adjusted independently for maximum flexibility in your applications

A conveyor belt system can be added to all LISSMAC machines combined controls allow for convenient operation

Advantages Over Manual Processing

Significantly higher productivity combined with superior quality

Consistent part quality

Improved and safer work environment for your employees

Automated process – no flying sparks, dust, dirt or excessive noise

Paint & Powder Coating

Edge rounding has been found to help paint and powder coatings adhere better to the part and help prevent future corrosion.

Rounding the top and bottom edges creates a better surface area for paint to adhere compared to a sharp, 90-degree edge where little paint can adhere to the edges.

Salt spray testing reveals that companies painting or powder coating parts benefit from rounded edges to achieve the best condition for paint adhesion.

Safety

In all applications, particularly the food and medical industries, the consistent rounding of sharp edges benefit both the workers on the shop floor and the customer.

An automated deburring and edge rounding machine is able to deliver a part that has a consistent and safe finish each time a part is sent through.

LISSMAC Sample Processing

LISSMAC will run your sample parts at our US headquarters’ demo center.

See your parts being processed via onsite demos, live web demos, or recorded video.

LISSMAC does not cut corners when running sample parts.

We demonstrate what the machine can really do in a single pass and share all details during the sample processing.

Contact us to arrange a demo or sample part processing anytime.

Specifications

|

Machine Model |

G1-S2-1000 / G1S2 1500 |

|

Working Width Max |

39.5" / 59" |

|

Workable Material Thickness |

.020" - 2" |

|

Voltage |

480 V / 60 Hz |

|

Total Power |

39 A - 41 A |

|

Total Current Consumption |

16,8 kW - 22 kW |

|

Insulation Class |

IP 42 |

|

Infinitely Variable Feed Speed |

0-130 FPM |

|

Adjustment of Tools |

Electric |

|

Adjustment of Material Thickness |

Electric |

|

Weight |

5,511 / 6,172 lbs |

|

Dimensions (W/D/H ) |

|

|

G1-S2-1000 |

110"/60"/70" |

| G1-S2-1500 | 129"/60"/70" |