Haeger 824 MSP

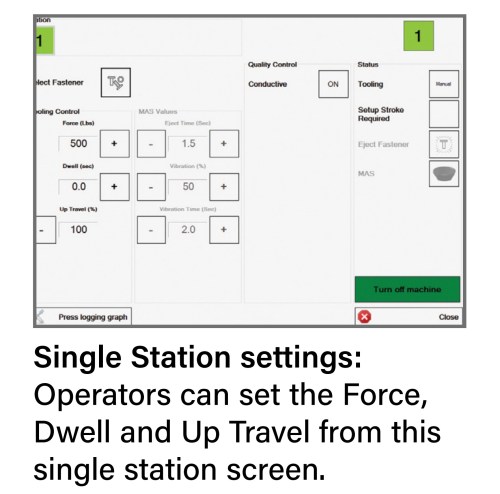

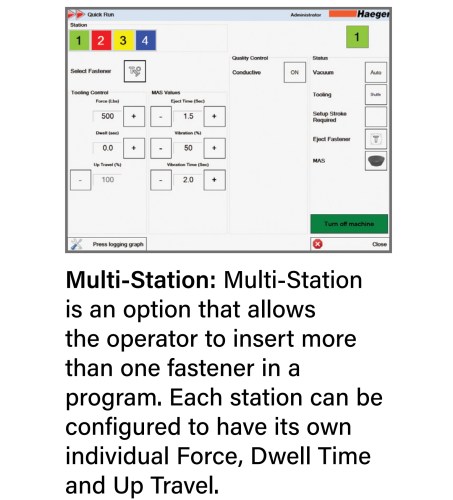

The 824 MSP Machine includes a PLC Touch Screen and a Manual locking 4 Station Turret Insertion System which enables the insertion of up to four different fasteners in one part handling, providing a productivity boost of 60% or more while having a lower cost for today’s economy.

The hydraulic machine delivers 8 tons of ram force, with a 24-in. throat depth. Its positive-stop cylinder is designed for use with soft materials such as aluminum so that fasteners can be inserted without crushing or deforming the part.

Haeger 824 MSP Hardware Insertion Machine

The 824 MSP is fully hydraulic, 8 ton of force, 24" throat depth, 4 station lower turret, and is powered either by 208, 220, or 480 three phase.

The options available are hand crank, auto feed, and Laser Light. Positive Stop, TPS (Tooling Protection System) and Batch Counter, are standard on the 824 MSP.

Features added to standard equipment

Tooling Protection System and Batch Counter

The 824 MSP is best suited for mid to high volume parts with fasteners up to 0616 ( M10 ) in mild steel and 0516 ( M6 ) in stainless.

This machine is also good for soft aluminum parts with the positive stop feature where force required is less than 1000 lbs.

The 824 MSP also has a 4 station lower turret where you can insert 1 fastener automatically and three different fasteners manually allowing you to get the benefit of single part handling.

Single Part Handling allows you to increase your process flow by inserting four different all with their own pressure settings and only handle the part once.

This feature eliminates the bottle neck. This machine however does not have quality control with fastener length, Fastener detection, or insertion mapping.

Benefits of the Haeger 824 MSP Hardware Insertion Machine

Manual 4 station turret allows insertion of 4 different fasteners in the same part handling

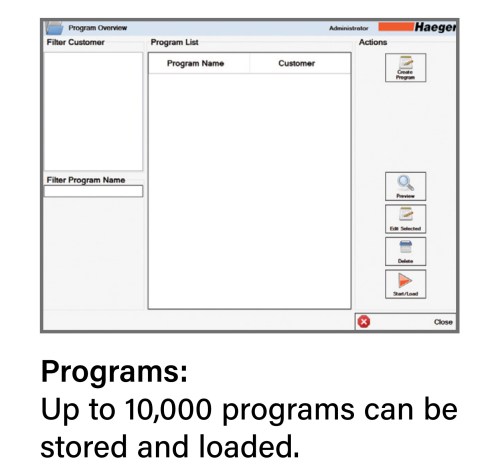

PLC touch screen to set force, dwell, up travel,Batch Counter and TPS for each station 8 tons of ram force; 24-inch throat depth

Fully hydraulic; PLC electrical controls

Equipped with Haeger's patented Safety System

Positive Stop Cylinder

The positive stop is designed for use with soft materials such as PC boards, plastics, fiberglass and aluminum—it allows fasteners to be inserted without crushing or deforming the part.

Haeger's patented Safety System, Variable Dwell Timer and Adjustable RAM Retract Position

Haeger's patented Safety System is effective at any point in the ram stroke irrespective of the tooling length, requiring no set up by the operator; thus not affecting initial machine set up time.

The variable dwell timer is available for inserting fasteners into stainless steel.

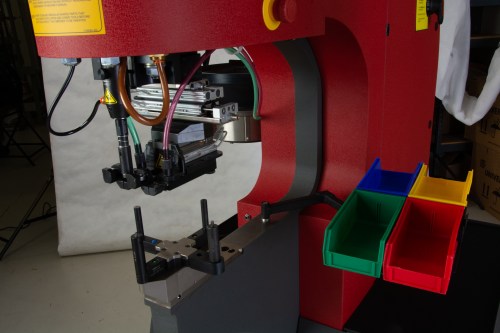

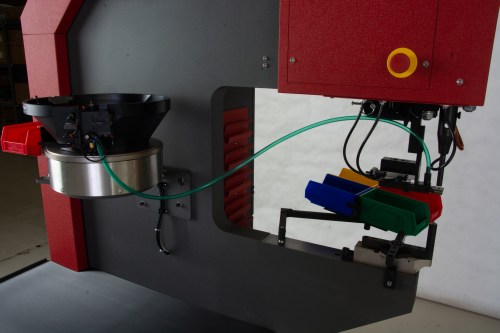

MAS (Modular Autofeed System)

The 824 MSP can be equipped with an optional MAS (Modular Auto Feed System) unit.

Auto feeding is three times quicker than manual insertion

Automatically orientate, singulate, and feed nuts, studs, and standoffs without having to change the auto feed bowl

Experience fast and easy tooling changeover, change-over from nuts to studs or standoffs in less than three minutes, and feed up to 2,000 fasteners per hour.

Specifications

| Force range | Adjustable 800 lbs. - 16,000 lbs. |

| Throat Depth | 24" |

| Stroke Length | Adjustable 0" - 8.5" |

| Electrical | 240/480 3 phase |

| Oil Tank Capacity | 22 gal. |

| Motor | 5 hp |

| Speed | Up to 1,400 fasteners per hour |

| Repeatability | + or - 2% of force setting |

| Weight | 2,800 lbs. |

| Footprint | 59"L x 38"W x 94"H |

| Fastener Range | .256" - .500" (M2 - M12) |