LEMAS Three Roll Machines

Three-Roll Plate Bending Rolls

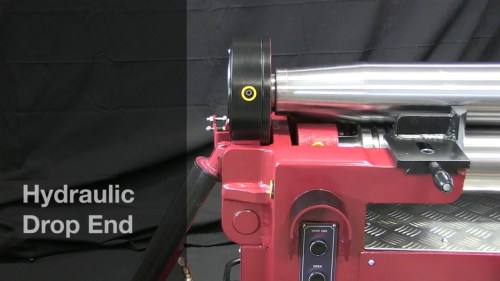

LEMAS initial pinch bending rolls feature hydraulic adjustment of the rear bending roll and the lower pinch roll. In addition, the rear roll is hydraulically tiltable for cone rolling, and the hydraulic drop end makes it simple to remove the completed cylinder from the rolls.

Unique to LEMAS initial pinch machines is the Quick and Easy pinch gauge adjustment. Consistent positioning of the lower pinch roll is critical to rolling consistent quality cylinders. By simply inserting a small tab of the material thickness to be rolled into the pinch gauge control, the lower pinch roll is properly positioned to ensure that consistency.

Sumitomo Cyclo® 6000 gearless speed reducers, featuring unique epicycloidal design, have advantages superior to speed reducers using common tooth gears. Unlike gear teeth with limited contact points, a Cyclo has two-thirds of its reduction components in contact at all times. This design enables Cyclo speed reducers and gear motors to withstand shock loads exceeding 500% of their ratings, and provide exceptional performance, reliability and long life in the most severe applications.

Other standard features include Direct-Drive Design using no belts, cone rolling attachment, rolls heat treated to 50Rc, digital readout for positioning the rear bending roll, and grooves for 1/4″, 3/8″ and 1/2″ round bar (except 80 series models).

The long list of standard features together with competitive pricing makes the LEMAS roll a continuing favorite of the metal fabricating industry.

Standard Features

Direct-Drive Design using no belts and featuring positive drive regardless of position of pinch roll

Sumitomo Cyclo® 6000 Gearless Speed Reducer

Grooves for 1/4”, 3/8”, 1/2” round bar (except 80 models)

Spherical roller bearings on all rolls for longevity and constant use.

Hydraulically powered rear bending roll. Raise and lower the bending roll hydraulically rather than a handwheel seen on other brands.

Power tilting rear bending roll for cone rolling

Cone bending attachment

Digital readout for position of rear bending roll

Hydraulically operated drop-end for quick removal of rolled product rather than using a pivoting roll.

Quick and Easy hydraulic lower pinch roll adjustment with pinch gauge control

Dual Forward/Reverse rotation controls – Console mounted and hand-held pendant.

Upper and lower pinch rolls driven with direct gear contact.

All rolls heat treated to 50 Rc.

Manual tilt of the lower pinch roll

Emergency stop cable

Hydraulic oil, tools, pinch gauge stock, technical manual

Options

Top Supports

Infinitely Variable Speed Control

Control Panel on Wheels

Specifications

|

Model |

Capacity |

Top Roll Dia. |

Drive/Hyd. Motor HP |

Weight/lbs. |

|

TR 80/3 |

3′ x 13 ga. |

3.15″ |

2 /½ |

1,720 |

|

TR 80/4 |

4′ x 14 ga. |

3.15″ |

2 / ½ |

2,100 |

|

TR 100/4 |

4′ x 11 ga. |

3.93″ |

2 / ½ |

2,200 |

|

TR 120/4 |

4′ x 10 ga. |

4.72″ |

2 / 1 |

2,820 |

|

TR 140/4 |

4′ x 3/16″ |

5.51″ |

5 / 1 |

3,500 |

|

TR 160/4 |

4′ x 1/4″ |

6.30″ |

5 / 1 |

3,880 |

|

TR 180/4 |

4′ x 3/8″ |

7.10″ |

5 / 2 |

4,600 |

|

TR 200/4 |

4′ x 9/16″ |

7.87″ |

5 / 2 |

6,500 |

|

TR 80/5 |

5′ x 16 ga. |

3.15″ |

2 / ½ |

2,025 |

|

TR 100/5 |

5′ x 12 ga. |

3.93″ |

2 / ½ |

2,325 |

|

TR 120/5 |

5′ x 10 ga. |

4.72″ |

2 / 1 |

3,200 |

|

TR 140/5 |

5′ x 3/16″ |

5.51″ |

5 / 1 |

3,800 |

|

TR 160/5 |

5′ x 1/4″ |

6.30″ |

5/ 1 |

4,250 |

|

TR 180/5 |

5′ x 5/16″ |

7.10″ |

5 / 2 |

5,100 |

|

TR 200/5 |

5′ x 1/2″ |

7.87″ |

5 / 3 |

7,100 |

|

TR 120/6 |

6′ x 11 ga. |

4.72″ |

2 / 1 |

3,800 |

|

TR 140/6 |

6′ x 10 Ga. |

5.51″ |

5 / 1 |

4,200 |

|

TR 160/6 |

6′ x 3/16″ |

6.30″ |

5 / 1 |

4,800 |

|

TR 180/6 |

6′ x 1/4″ |

7.10″ |

5 / 2 |

5,900 |

|

TR 200/6 |

6′ x 3/8″ |

7.87″ |

5 / 3 |

8,000 |

|

TR160/8 |

8′ x 10 ga. |

6.30″ |

5 / 1 |

5,425 |

|

TR 180/8 |

8′ x 3/16″ |

7.10″ |

5 / 2 |

6,575 |

|

TR 200/8 |

8′ x 5/16″ |

7.87″ |

5 / 3 |

9,000 |

|

TR 180/10 |

10′ x 10 ga. |

7.10″ |

5 / 2 |

7,700 |

|

TR 200/10 |

10′ x 1/4″ |

7.87″ |

5 / 3 |

10,100 |