NHC-130 SERIES

HIGH SPEED CIRCULAR SAWING MACHINE

Massive and Rigid Construction

Machine Weight 14,000 lbs.

Nishijimax high-speed circular saws are ideal for cutting solid bar stock, thick wall pipe and tube at extremely high production rates.

NHC-130 SERIES

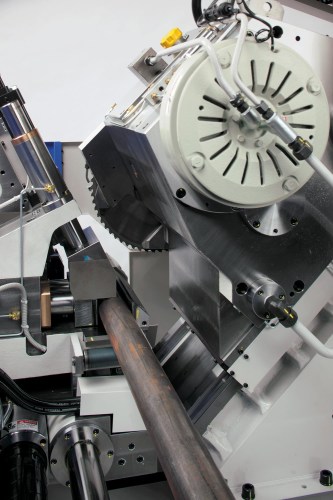

Z-CUTTING AXIS:

5.118" Cut Capacity, 45 Degree Wedge Cutting Axis with Linear Rails allows blade guides fixed closer to bar and keeps chips away from the saw spindle/hub.

The Ball Screw Servo Control of the Cutting Axis allows for independent Control of both the Blade RPM and the Chip Load per Tooth.

The precision Saw Blade Spindle and heavy-duty gear box reduction with powder brake removes all backlash delivering outstanding life of the saw blade.

The powered Chip Brush, that is centered on both sides of the cutting tip further extends the life of the saw blade, especially when cutting pipe and stainless steel.

Secure Clamping of the work piece on both side of the saw blade, insuring maximum blade life, as well as superior surface finish.

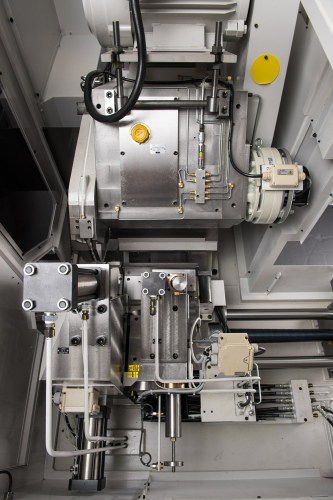

X-SIZER AXIS:

The X-Axis will index the length or bar or tube to a precise cut length.

This unit is ball screw driven and servo controlled.

It travels guide rails.

The sizer clamp has 3 positions to insure clean movement of the bar forward to the desired cut length.

The unit also has a retract motion after each cut to insure long life of the saw blade.

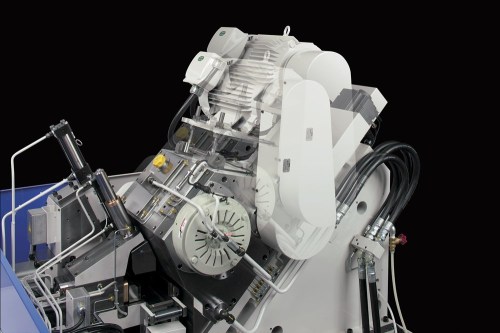

45 Degree Slant Bed Approach

Massive Saw head travels on Linear Rails on 45° slant bed design.

Feed rate control via AC Servo Motor & Ball Screw.

Sawblade Coolant Nozzle

6 Point Precision Blade Guides are positioned very close to the work piece.

Saw Lube at cutting tip.

Magnetic Power Brake

Magnetic Power Brake removes all backlash for long blade life.

Maintenance free and air cooled.

Horizontal & Vertical Clamping

Secure Horizontal & Vertical clamping of the work piece.

Material Handling & Automation

Pat Mooney Saws in-house design and fabrication shop builds bundle racks, load tables, and offload conveyors with robotic handling to make the most of your material flow.

Each Nishijimax machine has these next-step operations already embedded into the interface.

So, whether you need to combine operations or simply need to automate your production line, Pat Mooney Saws and Nishijimax makes it easy.