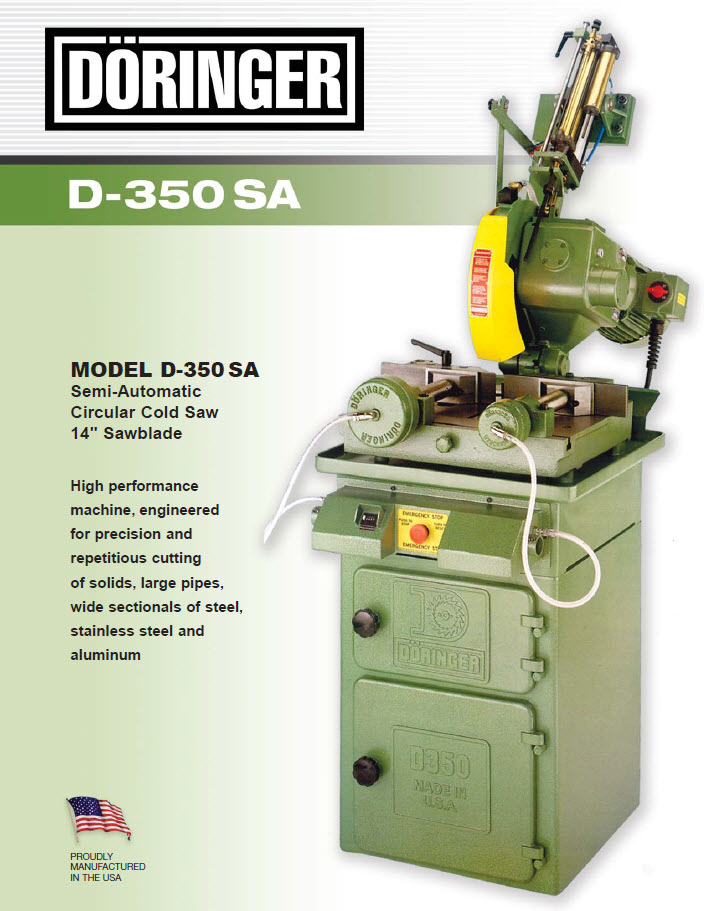

DORINGER Model D350SA

Semi-Automatic Circular Cold

Sawing Machine.

High Performance, Engineered For Precision & Repetitive Cutting Of: Solids, Large Pipe, Wide Sectionals Of Steel, Stainless Steel

& Aluminum

DORINGER Model D350SA

Semi-Automatic Circular Cold

Sawing Machine

High Performance, Engineered For Precision

Repetitious Cutting Of:

Solids

Large Pipe

Wide Sectionals Of Steel

Stainless Steel

Aluminum

Model D350SA Standard Equipment:

Power Down Feed Unit

Double Hinged Guard

Double Air Vice

Motor Switch

Pump Switch

Chip Container

Coolant Tank

2 Speed Motor

Emergency Stop

Two-Hand Control

Left & Right Vice Pressure Gauge

Model D350 SA Technical Specifications

Gear Box

Constructed of high-grade cast iron, precision machined. This is a direct drive motor to gear box, coupled via 2 piece coupler with a high resistance rubber pad between. This design generates optimum performance in a noise-free atmosphere. Maintenance free.

Safety Guards

Designed with safety and rigidity in mind there 2 piece inner and outer guards work as a shields to fully cover the sawblade and protect operator in any position of the head from accidental contact with sawblade.

Coolant System

Seal-less electric coolant pump is mounted on top of of removable large capacity coolant tank. Tank located in base of machine. Coupled with detachable hose to the coolant nozzle, based on top of inner guard. Flow is easily controlled by valve. Controlled and protected with switch, which gives user the convenience of turning the coolant system on-off and thermally protecting it at the same time.

Electric Motors

Model D350 - 3 HP Motor

Model D315 - 1.5 HP Motor

All Doringer machines are driven by AC constant torque motors. Every motor is protected with overload protection switch, set for your particular machine.

Due to a variety of materials customers are cutting, we offer at no extra charge the following motors:

Model Type "A": with a 2 speed switch,

Mounted on motor and set for:

On speed #1 - 1700 RPM for mild steel

On speed #2 - 3400 RPM for non-ferrous

Model Type "B": with a 2 speed switch,

Mounted on motor and set for:

On speed #1 - 850 RPM for alloys and stainless

On speed #2 - 1700 RPM for mild steel

The speeds shown above are motor speeds only, and are further reduced in ratio 1:31 which is the actual sawblade speed.

Motor RPM

850 - 1700

1700 - 3400

Sawblade RPM

27 - 54

54 - 108

Please specify voltage: 220v. 3ph or 440v. 3ph.

Turn Table

Constructed of cast iron class 40, used in the industry for precision parts and high resistance to wear, machined to tolerances not to exceed ±0.001". The flat base with scale conveniently marked on top also incorporates the turn table, which turns left and right for mitering purposes, without turning the workpiece.

Clamping Unit

Two Separate air cylinders are used to clamp material on place. Each individually adjustable for depth and air pressure. Total clamping power 8,000 pounds, if used with 100psi. Each cylinder could be easily moved left or right, allowing sawblade to finish the cut. Total movement forward of cylinder, when actuated is 0.250", which insures safety.

Downfeed Unit

Hydro-pneumatically controlled, with adjustable rapid movement downwards and return. Cutting cycle is totally controlled via bellows hydrocheck. As a safety feature, unit will not operate if electrical power is disconnected.

In upper rest position motor shuts itself off.

Control Panel

Ergonomically set for good visibility and safety. Unit must be 2 hand operated. Panic button is latching type and safety colored.

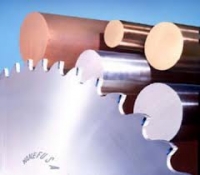

Sawblades

HSS Sawblades recommended only.

350mm (14") maximum size suitable.

Special applications might require smaller sawblades.

{aricsvtable file="csv/doringerd350SA.csv"}{aricsvtablecolumnspan row="0" startIndex="0" endIndex="3"}{/aricsvtable}