Komatsu Plasma

What is Plasma?

Plasma is the fourth state of matter along with solids, liquids and gases.

Plasma is an arc or beam of ionized gas capable of conducting electricity. The arc produces extreme heat of around 22,000 degrees.

This electrically conductive gas transfers energy from an electrical power source through a plasma torch to the material being cut.

Komatsu Plasma

Komatsu Plasma Cutting Systems are a cost effective alternative to laser cutters, by providing precision quality cutting at lower initial cost and production cost. The TFP3062 6 x 12 150 Amp (30kw). has a 6 x 12 ft. table, new FANUC 0iMC CNC, and rearranged gas controls for easier access next to the CNC. NC program storage capacity has been doubled. A USB port can be used to load NC programs. The new features are also part of the new model TFP3051 Mark IIIα 5 x 10. All Komatsu Plasma Cutters feature arc voltage height control. Marking is done using the plasma torch and argon gas.

The Quick Gas Oxy-Propane Option

The Oxy - Propane Attachment Option extends the steel maximum cutting thickness from one inch to two inches. Switching between plasma and oxy fuel cutting is accomplished in minutes by replacing the plasma torch cap with the oxy propane torch cap.

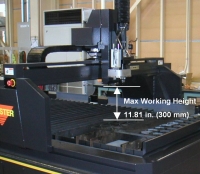

High Body Extended Z-Axis Stroke Option

For cutting applications involving large size square pipe and other structural members, order the TFP3051 with the High Body Factory Installed Option. With this option the TFP3051 Z-Axis stroke is increased to enable a working height increase from 5 in.to 11.8 in. without reducing cutting accuracy.