LISSMAC Machines: Overview

LISSMAC designed unique machines that can save up to 60% on your de-burring time with a Lissmac edge rounding technology by processing both sides of your part in one pass.

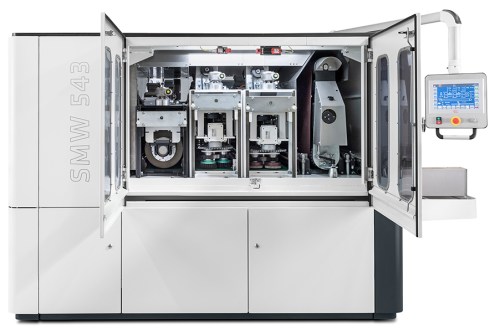

LISSMAC De-Burring Finishing machines

This LISSMAC series with its flexible configuration is a machine line designed for high-end de-burring and finishing of sheet metal parts and can be configured for wet or dry operation. The systems are also available in in single or up to 4 working stations to meet a wide range of applications.

The LISSMAC Company

LISSMAC continues to set new standards for innovative sheet metal processing with the development of a series of patented machines for steel brushing, grinding, and deburring.

LISSMAC's highly effective method of processing both inside and outside contours of sheet metal parts in just one single pass is unique to the market.

LISSMAC Innovation: Both Sides in One Step

LISSMAC designed a unique series of machines that can save up to 60% on your de-burring time with Lissmac's edge rounding technology.

With typical belt machines you must send your parts through twice to do the same work.

In one pass LISSMAC machines will process both sides of your part!

The unique method of simultaneously grinding, de-burring, and edge rounding on inside and outside contours of laser, plasma or flame cut parts in one single pass is very efficient.

LISSMAC De-Burring / Finishing Machines

LISSMAC's single sided conventional de-burring, finishing machines are available in both wet & dry operation.

Several models in this series are built with a modular principle; with systems available from single head configurations to up to 4 work stations to meet many different customer requirements.

LISSMAC Sample Part Processing

LISSMAC will run your sample parts at our US headquarters’ demo center.

See your parts being processed via onsite demos, live web demos, or recorded video.

LISSMAC does not cut corners when running sample parts.

We demonstrate what the machine can really do in a single pass and share with you all details during the sample processing.

Contact us to arrange a demo or sample part processing anytime.