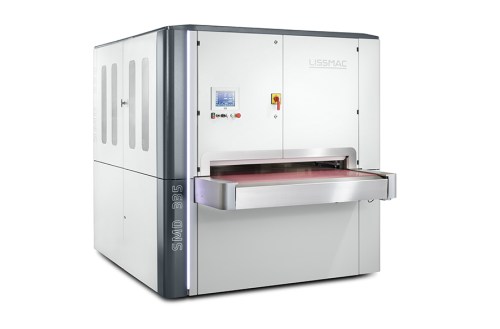

LISSMAC SMD 3: Dry, Single Side, Deburr, Edge Round & Surface Finish

The SMD 3 S-Edition is ideal for processing laser and punched parts and also for deburring small thin sheet metal parts.

The S-Edition gives impressive results on the part edge and surface sanding.

The dry grinding and deburring machines can be used to remove excess burrs, as well as producing a good surface finish and edge rounding up to a radius of .080".

Stainless steel, steel, aluminum and non-ferrous parts can be processed.

Edges can be rounded over the entire working width of the machine.

LISSMAC SMD 3 Series

Universally applicable for thin sheet processing, the LISSMAC 3 Series S-Edition machines will convince you with their efficiency and top processing results.

In single-sided and dry processing, burrs and the laser oxide layer can be removed, as well as creating strong edge rounding or a surface finish.

Features

Suitable for processing various materials including steel, stainless steel and aluminium

Individually adjustable processing parameters for optimum results

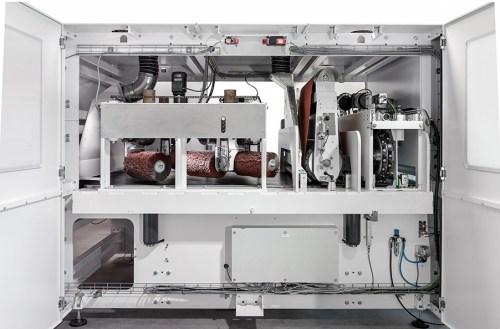

The thought-out design of the rotary heads ensure an even processing result over the whole working width

Maximum tool contact with the workpieces for perfect edge rounding up to .080" radius

Efficient processing of small parts (down to 2" x 2"), whatever the geometry of the pieces

Stationary machine table - Constant table height for ergonomic work

Intuitive operation thanks to clear touch panel

Flexibility and energy-efficient work because the processing units can be switched on and off separately

Fast machine setting by automatic positioning of the tool axes

Program memory takes care of automatic machine settings and reproducible processing results

Fast tool-changing system keeps set-up times to a minimum

Wide range of tools for maximum flexibility

Optimal machine accessibility facilitates cleaning and maintenance

Window in the machine doors allows to monitor the process

Appropriate options and features for individual customer requirements

Possibility of automation & integration in production lines

LISSMAC S Edition

Versatile for all customer requirements - from R2 edge rounding to finishing

Uniform edge rounding and multi-directional finish thanks to several brush heads

Creation of high-end grinding patterns and strong edge rounding

Processing of sheets with coating, laser foil, imprints or punched-out holes

The LISSMAC SMD 335 DRE is designed, to remove slag, deburr and edge round your parts after oxyfuel or plasma cutting. With parts as small as 2x2" on the magnetic track we also can clean up parts up to 53" in width and 4 inches thick.

Specifications

| SMD 335 REE | SMD 335 DRE | SMD 345 REER | |

| Max. Part Width | 53" | 53" | 53" |

| Part Thickness Range | .040" - 4.72" | .040" - 4.72" | .040" - 4.72" |

| Voltage | 480/60 Hz | 480/60 Hz | 480/60 Hz |

| Total Current Consumption | 47 amps | 69 amps | 75 amps |

| Total Power | 23.6 kW | 35.6 kW | 38.6 kW |

| Variable Feed Speed | 1 - 26 ft./min. | 1 - 26 ft./min. | 1 - 26 ft./min. |

| Weight | 10,362 lbs. | 11,464 lbs. | 12,787 lbs. |

| Dimensions, (W/D/H) | 7 x 11 x 7.5 ft. | 7 x 11 x 7.5 ft. | 7 x 12.5 x 7.5 ft. |