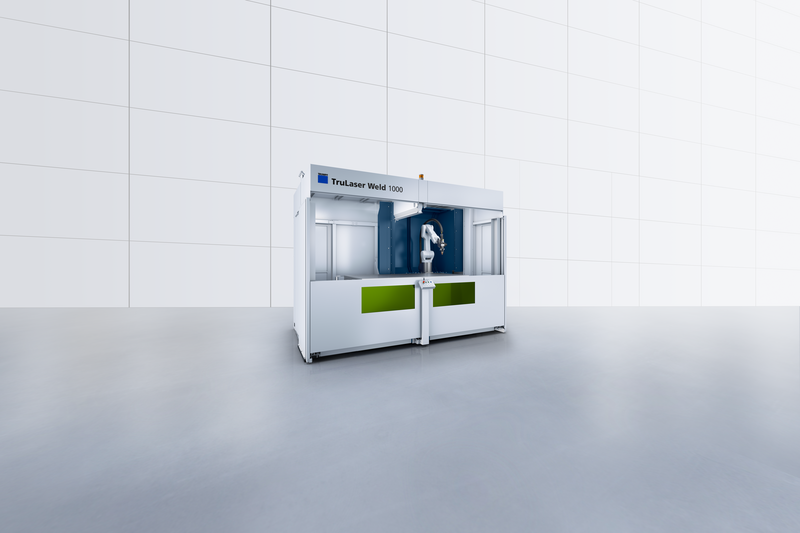

TruLaser Weld 1000 Series

TRUMPF's TruLaser Weld 1000 combines particularly simple operation and programming with the advantages of laser welding.

Weld faster, reduce rework, and still grow despite the shortage of skilled labor.

TruLaser Weld 1000 Series

The demand for simple automation for time-intensive welding is enormous.

TRUMPF's TruLaser Weld 1000 combines particularly simple operation and programming with the advantages of laser welding.

Weld faster, reduce rework, and still grow despite the shortage of skilled labor.

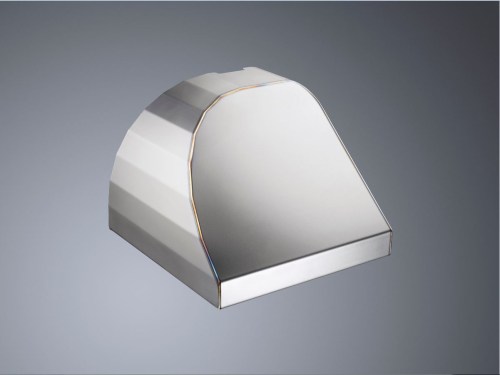

Optimum Welding Quality

Get the first-class quality, productivity and design freedom of lasers for your company.

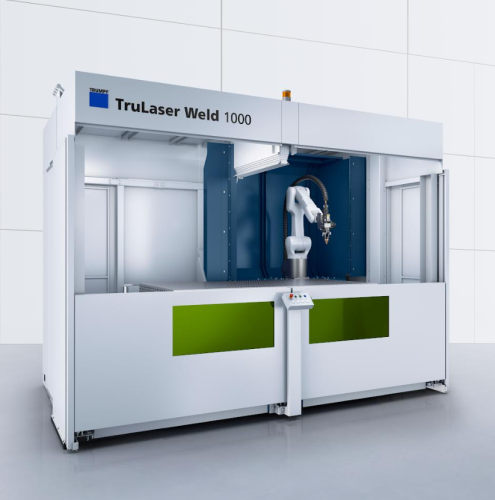

Easy Operation

Your team will operate and program the welding cell after just one e-learning session.

Clever operating units and visual support ensure this.

Flexible Production with One or Two Stations

Depending on demand, you can weld one large component or smaller ones in serial operation working parallel to production.

Set Up & Start Welding

Machine installation is completed within a day.

Welding parameters? They come with the machine!

Programming

With the ingeniously simple programming concept, users can program the industrial robot without any knowledge of the robot code.

Operators with no knowledge of robotics can use the optional operating units for simple programming.

Welding Optics

On the welding optics, you switch between heat conduction and deep penetration welding.

An integrated camera helps in finding the right waypoints.

Shielding Gas Nozzle

The coaxial shielding gas nozzle with integrated cross-jet protects the melt in every direction from oxygen input and the processing optics from welding steam and spatter.

A linear attachment provides optimum protection of the weld seam from oxidation.

TRUMPF's Techset Data Base

Receive an extensive collection of predefined welding parameters with the machine.

This makes programming even faster.

Simply select the suitable data record for the welding path, depending on sheet thickness, procedure and material.

Industrial Robot

The KUKA robot KR 10 with its six axes moves with agility and extreme precision.

Linear Axis

During two-station operation, the robot shuttles along the linear axis between the right- and left-hand stations.

During one-station operation, it utilizes the movement space for improved positioning of the welding optics.

Safety Cabin

The monitored safety cabin with integrated suction system, laser protection and lighting ensures safety.

The extendible partition wall divides the work area for two-station operation if required.

There is optimum access to the system thanks to sliding doors on the left and right as well as two hinged doors at the back.

Work Table

You can fix the components on the work table with positioning accuracy.

Standardized clamping systems or fixtures are suitable for positioning the components.

The table plate is fitted diagonally with system holes .630" (16mm) in a grid of 1.96" x 1.96" (50 x 50 mm).

The table's dimensions are 78.75" x 78.75" (2000 x 1000 x 100 mm).

Rotary Axes

An additional axis for rotating components extends the positioning options.

The two pneumatic rotary axes allow for synchronized positioning of components or fixtures, improving accessibility and productivity.

Digital Connection & Integration

Seamless integration of multiple TRUMPF machines into your own software environment is very easy.

We have the right solution for every combination, whether it be integration into TRUMPF's Oseon or a connection to monitoring and analysis tools.

A connection to third-party software systems is also possible with our interfaces based on the OPC UA standard.