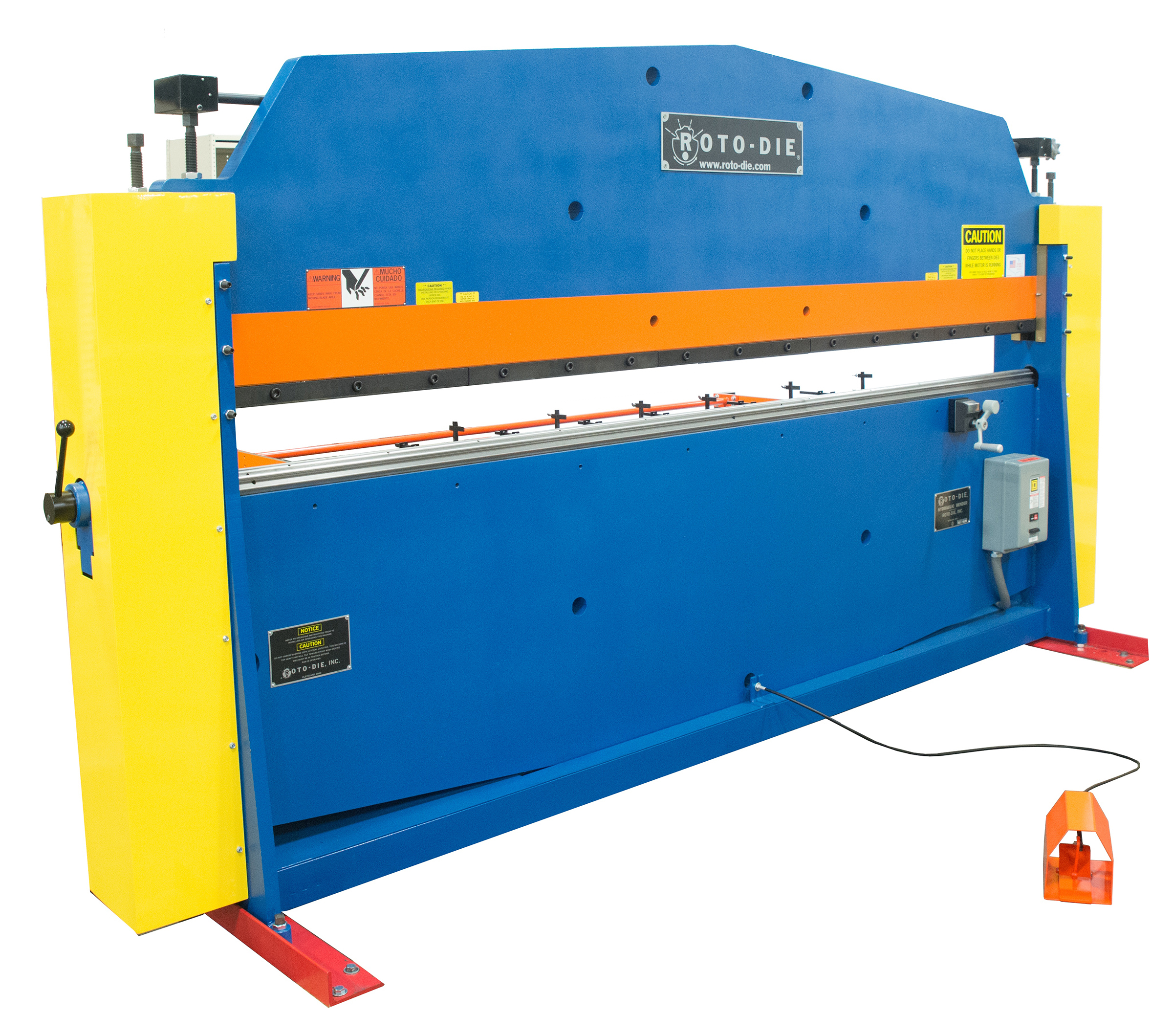

RotoDie Press Brakes

Productive - Most sheet metal configurations can be formed with just one handling by one operator.

Profitable - Roto-Die Hydraulic Press brakes are engineered to cut costs – labor costs are reduced while shop productivity is increased.

The patented Roto-Die hydraulic sheet metal benders have been a fixture in thousands of sheet metal shops for over 45 years.

Roto-Die is as simple to operate as a hand brake with infinitely more production capacity.

Over 45 years of hydraulic sheet metal bending experience at your fingertips

Roto-Die’s unique hydraulic sheet metal bending brakes are regarded as an industry standard in HVAC and metal fabrication shops throughout the United States. Each sheet metal brake is a versatile, economical, productive tool satisfying a wide range of sheet metal bending and forming needs. We use heavy-duty hydraulics in all of our sheet metal brakes, making bending operations quick and easy – today and for decades to come. Roto-Die hydraulic sheet metal benders capable of making accurate bends from 24 inches up to 12 feet in length. Capacities range from 16 gauge down to 10 gauge steel.

-

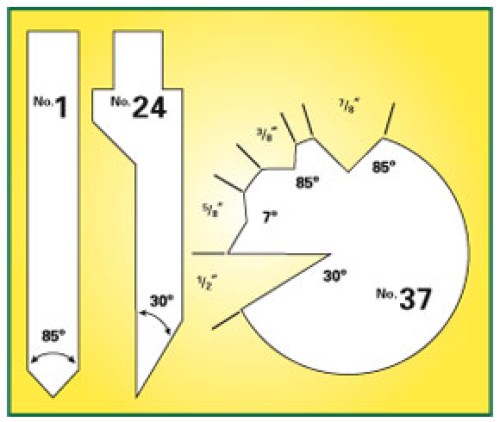

By shifting the selections lever, a single operator can perform all basic sheet metal forming operations.

-

No dies to change.

-

The Roto-Die hydraulic bender forms full-length ducts, gravel stops, standing lock seams, flashing, and hemming operations accurately and economically.

-

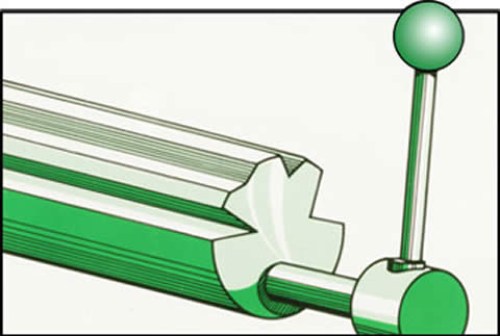

The compactness inherent in the cylindrical die design permits acute reverse bends not possible with conventional wide-bed machines.

-

All Roto-Die press brakes index quickly and accurately to all forming stations.

-

Automatic detention assures positive die alignment.

-

Centerline machined upper dies are instantly interchangeable in all Roto-Die openings without special stops or adjustments.

Roto-Die hydraulic press brakes reduce labor costs while increasing productivity.

-

The patented Roto-Die principle reduces setup time by as much as 70%, compared with other power-forming equipment.

-

Gauge and clearances are adjusted much quicker than on conventional hand brakes.

-

One-man operation cuts labor requirements in half on virtually all press brake operations.

-

Simple adjustments permit operating speeds up to 50 strokes per minute for maximum production output.

-

Multiple handling of sheet stock is kept to a minimum.

-

This allows you to fabricate most commercial ventilating jobs, including the new TDC duct system, in one-fourth the time that ordinary benders require.