Iowa Precision Pro-Fabriduct

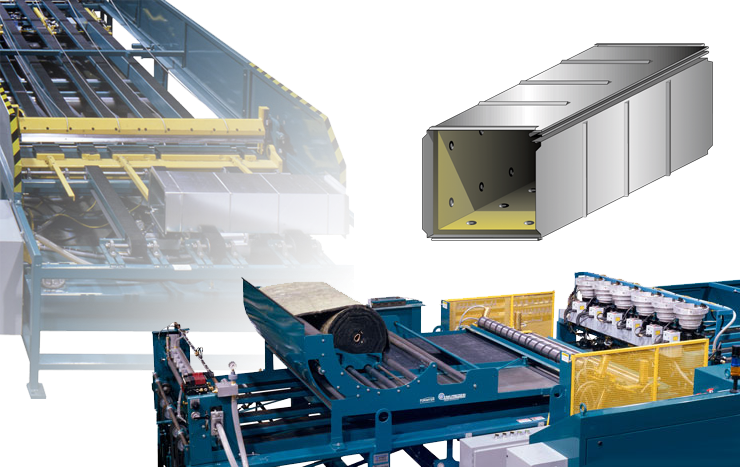

Start to finish fully automated duct fabrication line. Turns coiled sheet metal into finished, ready to install duct sections in "L" or wrap configurations.

Truly the most Advanced Complete Coil Line produced in the industry today. Leverages footprint, speed and production rates along with tolerances NO other HVAC coil line can match!

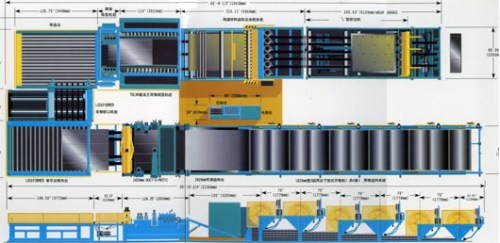

Modular design with 11 integrated flexible workstations

"U" or "Z" lay-out configurations to optimize floor space

Truly the most Advanced Complete Coil Line produced in the industry today. Leverages footprint, speed and production rates along with tolerances NO other HVAC coil line can match!

Modular design with 11 integrated flexible workstations

"U" or "Z" lay-out configurations to optimize floor space

Description

Pro-Fabriduct

Truly the most Advanced Complete Coil Line produced in the industry today.

Leverages footprint, speed and production rates along with tolerances NO other HVAC coil line can match!

- Most economical footprint in the world.

- Fastest feed rate in the industry.

- E-Z load coil drum assemblies (no lifting devises to add to your lift truck).

- Soft start motors for long life.

- Direct hydraulically driven decoilers system on every coil station with hydraulic hold downs and low friction pockets.

- Grid Skate Roll System for every coil station.

- Coil Select for feeding material into the coil processor.

- Industrial designed solid block die construction for a 25 year die life.

- The industry's toughest and most stable frames.

- Structured steel tube construction-maintains structural strength, & allows accessibility for maintenance & service.

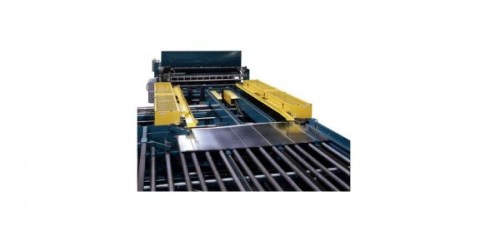

- Full width contact feed rolls for positive accurate movement.

- Engineered with heavy-duty left/right synchronization to stabilize cutting action and give

- the lowest moving mass, thereby reducing shock and vibration during the cutting stroke.

- Quiet operating system with a sound level less than 67 DB.

- Shear head squaring system designed for "tool free" adjustment.

- State of the art control designed, manufactured and serviced by Iowa Precision.

- Industrial, solid-state PLC touch screen operating system controller with storage recall.

- Tie Rod hole punching comes standard with both 5/16 and 7/16 punches.

- Swing Knife Insulation cutting system for both fiber and non-fibrous insulation.

- Solid state B & R controls with industrial quality/reliability; operator intuitive interface and graphics.

- Servo driven high speed wrap brake.

- Remote diagnostics and fast 24 hour service.

youtube_url

https://youtube.com/watch?v=jeitL7AVkVQ

Youtube URL address

https://youtube.com/watch?v=MGomz6piU8o

Youtube URL address