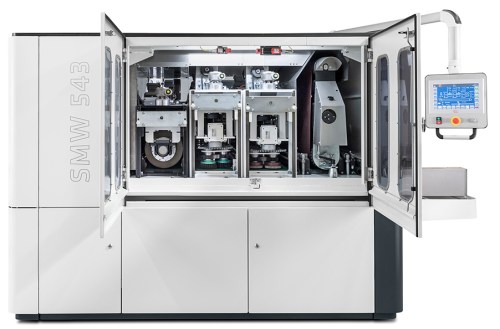

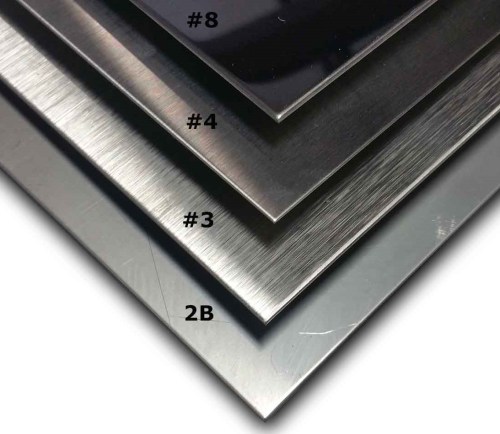

LISSMAC SMW 5 Series: Wet, Single Side, Deburr, Edge Round & Surface Finish

Having height adjustable heads brings great flexibility to a deburring or finishing machine as it allows the user to apply the desired amount of pressure to the surface of a part. This also leads to extended life of the abrasives by compensating for wear.

The LISSMAC SMW 5 Series

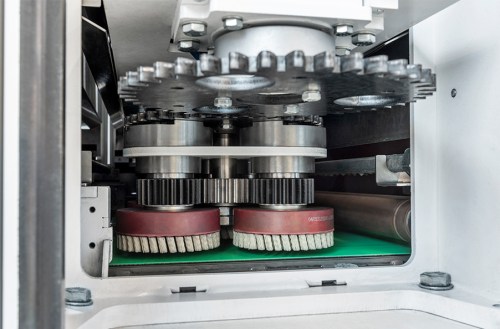

For perfect surface finishes using the wet grinding process. The machine can have up to 4 heads; 1) R-Roller Drum, 2) T- Top Brush, 3) P-Planetary, 4) B-Barrel Brush.

The 10“ PLC touch screen control of the LISSMAC is simple to understand and easy to use. Each application may require different settings. You can save set up time by storing, and easily recalling over 1,000 different programs in the PLC terminal.

Every critical part of the machine is kept away from the coolant. All electrical components like motors, frequency inverters and switches are placed in a dry zone. The bearings are sealed to protect them from fluid infiltration.

Spindles for raising and lowering the machine. The entire machine is lifted by four spindles when the part thickness is being adjusted. These spindles are all in the dry zone making sure they are kept clean and maintain their accuracy.

All heads in the 5 series have an independent height adjustment. This is a huge advantage when working with different types of abrasive belts such as thick non-woven belts and thin micro finishing belts.

Having height adjustable heads brings great flexibility to a deburring or finishing machine because it allows you to apply the desired amount of pressure to the surface of a part. This also allows you to extend the life of the abrasive by compensating for wear.

A drying station is a standard feature on all 5 series wet machines. Parts are squeezed dry by squeeze rollers. There are also two air knives above the part and two air knives below the part to ensure that no fluids remain on the parts after leaving the machine.

The 5 seriesr filtration system is integrated within the footprint of the machine. This reduces the amount of shop space needed for the machine. The filtration system is designed with easy access for maintenance and cleaning.

Description