Haeger 618 MSP

Haeger 618MSPe

The 618 MSP is fully hydraulic, PLC Touch Screen with Program Storage & Part Complete Screen, 6 ton of force, 18" throat depth, and is powered either by 208, 220, or 480 three phase.

The options available are Positive Stop with or without hand crank, auto feed, TPS ( Tooling Protection System ), Batch Counter, and Laser Light .

The 618 MSP is best suited for low to mid volume parts with fasteners up to 0616 ( M8 ) in mild steel and 832 in stainless.

This machine is also good for soft aluminum parts with the positive stop feature where force required is less than 1000 lbs.

NEW!...Features added to the standard equipment: Tooling Protection System and Batch Counter

Haeger's Proven Safety System

Safety system is always in effect; requires no set-up or adjustment by the operator at any time.

Allows the operator to work quickly and confidently, without cumbersome tool guarding.

Reliable Hydraulic Power

Safe, even application of pressure ensures proper seating of fastener.

Ability to apply pressure at any point in stroke.

Ability to jog ram up or down.

Reversible at any point in the stroke.

Universal Electrical Control

24 volt control conforms to applicable UL, Canadian CSA, and European CE safety standards.

18 inch Throat Depth

Allows easy access to large parts (for larger parts see Haeger's 824 and 840 series machines).

Interchangeable Tooling

Manual and automatic tooling for all Haeger Press models are interchangeable.

Versatile

Accepts optional part marking attachment.

Accepts optional press joining tooling.

Tooling Protection System

Monitors machine operation to protect tooling from damage.

Significantly decreases risk of part damage during hardware insertion.

Designed for easy set up and operation.

Electronic Batch Counter

Confirms that the fastener count with an audible signal, and tracks completed parts.

Ram Dwell Timer

Allows additional time for the fastener and the material to form a strong clinch before the ram retracts.

Essential for quality results when working with stainless steel material.

Positive Stop

Haeger's 618 optional positive stop cylinder to gives precise control over insertion depth.

Great for delicate materials or for fasteners vulnerable to crushing.

Work Light

Provides general illumination of work area.

Part Locating Light

Pin-points a cross-hair of light to aid operator in locating holes on larger parts.

Increases productivity and decreases operator fatigue.

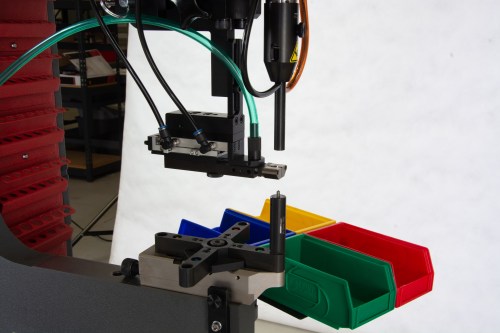

Automatic Feeding

Haeger's Modular Autofeed System (MAS) used with our new "Surefire" tooling, can triple your fastener insertion productivity.

Haeger MAS's can be retrofitted to any Haeger insertion machine. And Haeger tooling can be used on any Haeger machine.